By Kim McDarison

Some 20 people gathered Saturday at the Wisconsin Makers building in Whitewater to watch an annual event: a team of iron workers clad in protective clothing and face shields turning iron into art.

The event, known to its regular participants as “the iron pour,” is in its sixth year at the Wisconsin Makers building and in its second as a memorial to the late Pete Spangler, a former Fort Atkinson resident and a founding member of the nonprofit makers group in Whitewater.

Al Jewer, president of Wisconsin Makers, Inc., said the day began Saturday morning as pour participants arrived to purchase and make scratch block molds. The sand-based 5- by 5-inch blocks are soft enough to received a hand-scratched design, but strong enough to contain molten iron until it solidifies into a tile. The blocks are next broken apart and the tile is set aside to cool. The process completes when a member of the pour team smooths away rough edges with a wire brush and presents the tile to its artist.

On Saturday, the pour team estimated it filled with iron some 25 scratch blocks and six molds brought by members of the team.

Led by University of Wisconsin-Whitewater Art Department metal studio instructor and co-owner of Wisconsin-based Cowyard Studio Teresa “Tree” Lind, this year’s five-member team was composed of Mary Abbott, a volunteer agent who serves in the sculpture studio at UW-Whitewater, alumnae Taylor McDarison and Bee Krueger, and Gregory Brulla, a seasoned pour team member and friend of Lind’s. All of the members of this year’s pour crew have assembled as team members at previously held Whitewater pours.

As the team worked to transport molten iron from the furnace to the molds, eager artists and spectators photographed the process and enjoyed brats and snacks which were made available for purchase by the makers group.

Jewer explained that proceeds from the event would be used to fund the group’s ongoing projects, such as a free art class offered each Thursday to members of the community.

The group also is actively seeking new members, he said. Those who join the Wisconsin Makers group have access to the building’s full array of shops and equipment, ranging from woodworking, to weaving, to 3D printing, Jewer said.

During the event, Lind shared with the assembled group some information about the iron pouring process. Lind noted that “Dorito-sized” pieces of iron are loaded into a specialized furnace called a cupola. When loading the cupola, she said, the ideal recipe is about 20 pounds of iron layered with three pounds of coke, a specialized porous coal-based compound with a high carbon content and few impurities. The material is used to help the cupola burn at a high temperature without transferring impurities into the molten iron.

When ready, the molten iron is transported by a two-man team using a device called a crucible. Iron that is poured into molds is kept free of slag by a third crew member using a device called a skimmer. Slag is a term for impurities created by iron, coke and fluxing agents that pool on top of the molten iron.

This year, Jewer said, he was impressed by the designs artists scratched into their blocks, with some, including his son, Willy, experimenting with laser engraving tools.

One artist made his design using a CNC or computer numerical controlled router, he said.

Pour participants crafted a broad array of designs. Isabella Valdez, a college student from Albuquerque, N. Mex., said her design included a “schwa” which, she said, is the phoneme for the letter “A.” She arrived at the pour with Madison resident Kyle Mayer. He made a spider, he said.

Beloit resident and the director of Studio 84 in Whitewater Ben Kelly said he made a design that incorporated the initial of his last name with the year in which he purchased his home.

Another artist, Bill Brulla, said he did not make a tile. He is a participant in the Thursday art class offered at the makers building, he said, adding that he came to see what the pour was all about and work on his drawing skills.

After watching the team work, Brulla said it was “amazing to think about what they are doing. It’s a technique that people used to do, but you don’t hear about it anymore.”

Jewer said discovery, curiosity and experimentation is what the Wisconsin Makers group is all about.

During the COVID-19 pandemic shutdown the group lost a lot of its members, he said. Since then, membership has begun to rebound. The building also has been reconfigured to engage makers with multiple inviting and well-equipped work spaces.

Jewer said that while the annual iron pour had over the years become a treasured tradition, with Spangler’s passing, it has gained a deeper significance.

“It was Pete’s favorite event,” he said, adding that last year, when he died, “he just barely missed that one. He would have been thrilled to know that it has continued on and is gaining strength,” he said

An earlier story about Wisconsin Makers, Inc., Spangler’s contributions to the nonprofit organization and the annual iron pour is here: https://fortatkinsononline.com/pouring-iron-whitewaters-wisconsin-makers-group-to-host-tile-making-event/.

Photos from the event follow.

Taylor McDarison, from left, Gregory Brulla. Bee Krueger and Mary Abbott work together as a team to make and pour molten iron into a mold.

Bee Krueger, at left, and Taylor McDarison, at right, maneuver a crucible filled with molten iron. Mary Abbott, at center, assists with a skimmer. Pour team leader Theresa Lind removes scratch block molds that have already been poured.

University of Wisconsin-Whitewater Art Department metal studio instructor and co-owner of Wisconsin-based Cowyard Studio Teresa “Tree” Lind shares with event-goers the process used to melt and pour iron.

A cupola, a special furnace used to melt iron, is layered with pieces of iron and a porous coal-based compound called coke. The coke helps the furnace burn hot enough to melt the iron. The cupola bore the words “Pete’s Pour,” Saturday in recognition of the second annual memorial pour in remembrance of the late Pete Spangler, a Fort Atkinson resident who was among founders of the Wisconsin Makers, Inc., in Whitewater.

Iron tiles are broken free from their molds and left on a rack to cool.

Two photos above: At top, iron pour participant Willy Jewer, Madison, points to his tile as it cools; above, Jewer’s tile, shown center left, carries a symbol from a tabletop game called Warhammer 40,000. Jewer said he used a laser engraving tool, an X-Acto blade and a screwdriver to etch his design into his sand block mold.

Two photos above: At top, Fort Atkinson resident Bill Brulla sketches iron pour team members Saturday. Brulla said that while he did not make a tile, he was interested to watch the pour and practice his drawing techniques. He is a participate during the drawing classes held at the Wisconsin Makers building each Thursday; above, Brulla displays his sketches.

Wisconsin Makers, Inc., President Al Jewer, at left, enjoys the weather while Wisconsin Makers member Kent Taylor serves brats to a patron. Taylor’s friend, Denise Truitt, not pictured, helped cook the brats. All three individuals are from Milton.

Isabella Valdez, a student from Albuquerque, N. Mex., and Kyle Mayer, Madison, enjoy a snack while they wait for their scratch block mold tiles to cool. Valdez made a “schwa” which, she said is the phoneme for the letter “A.” Mayer said he made a spider.

Cooled and wire-brushed tiles are made available to their owners.

Tiles sport symbols and designs turning iron into art.

Iron pour crew member Gregory Brulla, at left, presents Beloit resident and director of Studio 84 in Whitewater Ben Kelly with his tile.

Beloit resident Ben Kelly displays his tile. The design incorporates the initial of his last name and the year in which he purchased his home, he said.

Pour team members Taylor McDarison, at left, and Gregory Brulla take a break while they wait for scratch block mold tiles to cool.

A 3D scanner is on display inside the Wisconsin Makers building. The device is one of many available for use by Wisconsin Makers, Inc., members.

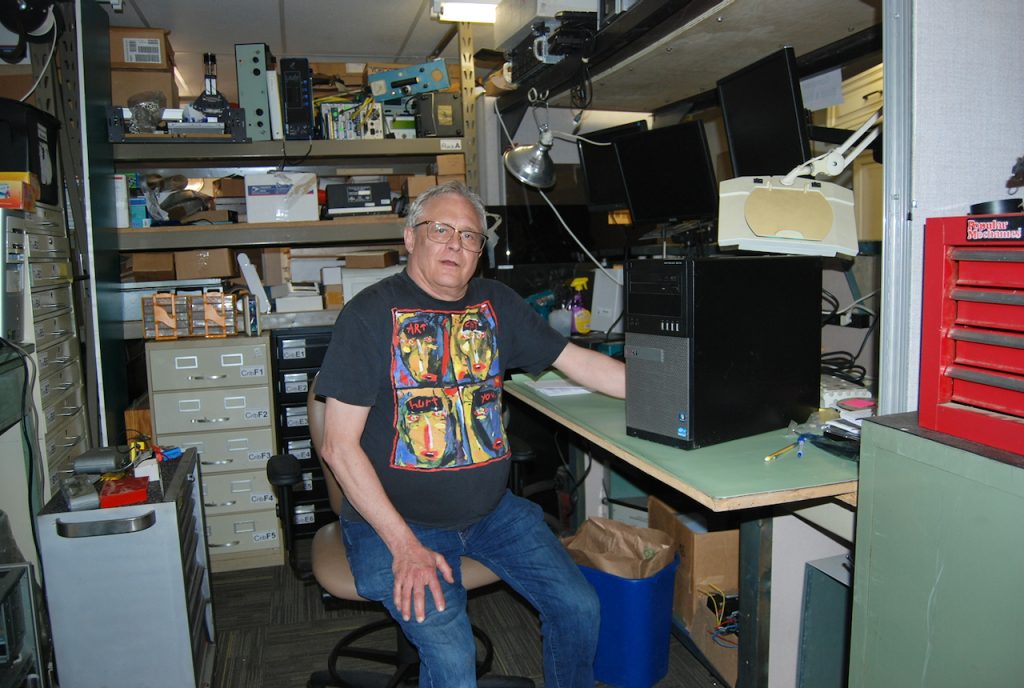

Two photos above: Al Jewer, president of Wisconsin Makers, Inc., offers a tour of several spaces inside the makers building, including the computer space, shown at top, which is adjacent to the electronics area, and a large gathering space, shown above, used by participants in an art class which meets each Thursday. Other spaces within the building include the woodworking area, machine shop, a textile space complete with looms for weaving, and a space which houses four 3D printers and a resin printer. To learn more about Wisconsin Makers, Inc., its equipment and membership, visit its Facebook page: https://www.facebook.com/wisconsinmakers/.

Kim McDarison photos.

This post has already been read 3834 times!