By Kim McDarison

Four Fort Atkinson High School students assembled Friday afternoon in the garage of their automotive education classroom to demonstrate some much-anticipated new equipment: a four-post lift and alignment rack.

The students, juniors, Spencer Brock, Braeden Church, Dominic Hebbe, and a senior, Travis Kutz, lifted a Ford F-150 owned by Kutz as their instructor, Justin Buntrock, talked about the value of the lift to his students and automotive instruction generally.

After arriving in need of assembly, the apparatus became fully functional Tuesday and has been in constant use since, Buntrock said.

Getting a lift

Buntrock, who has served as the automotive instructor at Fort Atkinson High School for four years, said the school already has a two-post hoist, but it has a limited capacity in the amount of weight in can lift, and it cannot lift trucks.

Getting a four-post lift that could be used by students to work on heavier vehicles, Buntrock said, “had been a conversation for a while.

“We knew we wanted a drive-on lift with an alignment rack built in.”

As conversations developed, Buntrock said, he was made aware of a fund that offered some potential to offset the project’s costs, “so I started digging,” he said.

Help came from McFarland-based Midwest Equipment.

“They knew of a shop called Wrecktify Collision and Restoration in New Glarus and they donated the alignment rack,” Buntrock said, noting that the equipment was valued between $3,000 to $4,000.

The lift itself was found through Craigslist, he said.

An automotive mechanic in Sussex was retiring, Buntrock said, adding: “He sold the lift to us at a reduced price when he learned I wanted it for a high school shop.”

Brand new, a four-post lift might cost $10,000. Used, Buntrock said, the lift had a value of about $7,000.

Next came the issues of logistics, Buntrock said, adding that Midwest Equipment transported the lift and installed it at the high school. Klement Towing and Recovery in Fort Atkinson brought the alignment rack to the school.

The alignment rack arrived first, he said, adding that it arrived about two months ago. The lift arrived about a month and a half ago.

Installing the new lift was a complicated process, Buntrock said. Midwest Equipment provided their expertise to install the four 6-inch by 6-inch and 10-foot tall metal posts.

“Everything uses heavy bolts and it’s bolted to the floor. Things had to be measured and placed precisely,” Buntrock added.

Along with posts, the lift has drive-on platforms and axel jacks, he noted.

Once the equipment was installed, it needed to be cleaned and made ready for paint.

“It was all hands on deck,” Buntrock said.

Students came during their free time to work on the project.

“When it came in, it was rough,” Brock said.

He and Hebbe were among students who volunteered their time to sandblast and wire-wheel the equipment until it was down to bare metal.

Buntrock and high school principal Dan Halvorsen painted the lift over a weekend.

From the moment the equipment arrived, Buntrock said of his students: “They were excited to have this.”

The value of automotive class

Under Buntrock’s tutelage, students learn theory and repair of small engines, and take classes in consumer, home and automotive; automotive 1 and 2, and advanced automotive.

He usually sees about 18 to 50 students in an automotive classroom setting and typically has 85 to 95 students participating in automotive classes each semester.

“I see a range of kids who are taking advantage of this opportunity. Some go into the workforce and others take it to learn how to work on their own vehicles. It’s a combination of both,” he said, adding that about 10% of his students are girls. Classes are open to all students, from freshmen to seniors.

Buntrock’s classes are included within the school’s CTE (career in technical equipment) curriculum, but, he said, it does link to the broader category of STEM (science, technology, engineering and math).

Buntrock said that while some of his students are looking at a career in the automotive industry, others are interested in becoming self-sufficient when it comes to their own vehicles.

It was a goal, he said, his own father set for him.

“My old man was a mechanic for about 15 years before I was born. He’s an electrician now. He taught me about mechanics,” Buntrock said.

Armed with those skills, Buntrock said, his brother did become a mechanic, but he didn’t see that path for himself.

Buntrock said as a high school student, he was inspired to learn and excel by many of his teachers. While in college, at the University of Wisconsin-Platteville, he said, he chose a career path so he could be that person for other students.

As an automotive instructor, he said, he finds opportunity to wrap his skills as an automotive mechanic into his teaching goals, which, he said, include inspiring his students as well as playing a supportive role through building a teacher-student rapport.

“My biggest thing for them, like my father wanted for me, was that I could work on my vehicles and fix things myself. That’s a skill set that creates self-reliance and saves money,” he said.

Sill, he said, students with professional aspirations are well-served through the Fort Atkinson High School program.

The shop is well-equipped. It has a tire machine for mounting and dismounting tires, a balancing machine, a parts washer, sandblaster, hydraulic press, transmission flusher, starter/alternator tester, air compressor for impact needs, a fully equipped exhaust ventilation system and a fully equipped toolroom.

“Students have a great opportunity here. If I was a shop looking to hire a technician, I would have confidence that students here have had a good education,” Buntrock said.

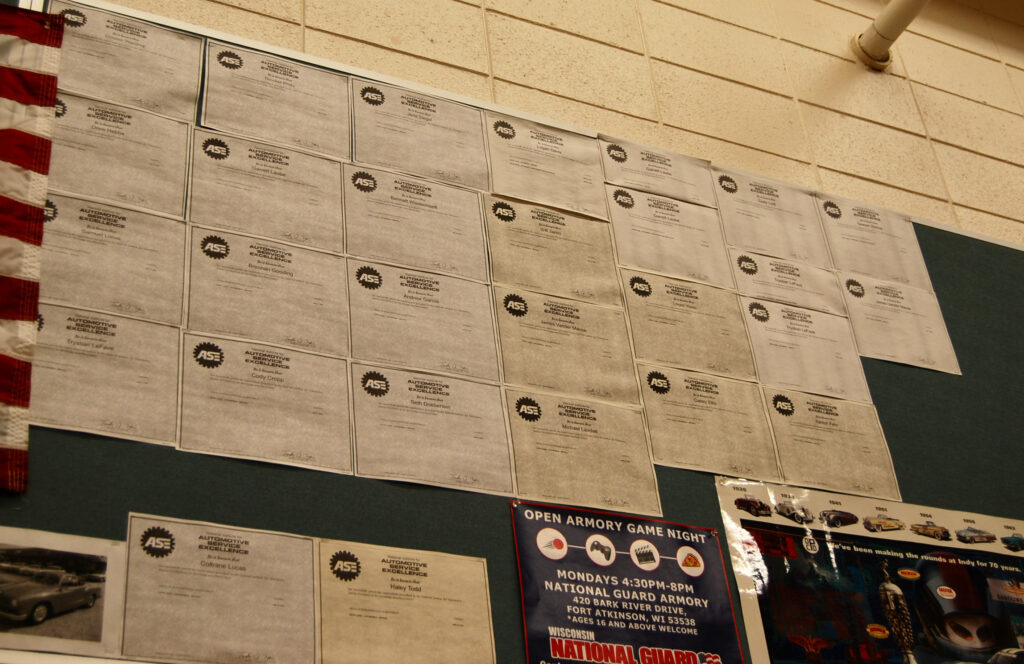

At Fort Atkinson High School, students can become certified by taking the ASE (automotive service excellence) test, which he described as “rigorous.”

“If kids walk in with one of those, it shows their knowledge in theory and repair,” he said.

“All of my students want to take it; it’s a goal. It’s a passed down bragging right,” he said adding about 40-50% of his students achieve certification each semester.

Benefiting the school community

The automotive shop provides benefits to the school community by offering automotive services, Buntrock said.

High school students and staff can get their cars aligned by the students enrolled in automotive classes at no charge.

“We ask them to pay for the materials if they are needed,” Buntrock said.

“Whatever students are learning, that’s what we offer. Students can do oil changes, tire rotations, brake jobs, a 27-point inspection, and suspension work. The program is very popular and students and staff take advantage of it,” he said.

The new lift expands opportunities for students by not only increasing what students themselves can learn, but increasing the services they can offer to the broader population.

“I’ve always had a passion for working with my hands and doing automotive stuff. My dad, he wanted me to have a better knowledge of automotive repair than him and that trickles down to my students. I want them to have better knowledge than me. I also want them to be able to fix things on their own,” Buntrock said.

His next dream, he said, is to build a bigger shop.

Fort Atkinson High School automotive students, juniors, Braeden Church, from left, Spencer Brock, Dominic Hebbe, and a senior, Travis Kutz, gather tools and prepare to demonstrate the value of being able to lift a Ford F-150 owned by Kutz. The new lift, which was delivered to the school just under two months ago became fully operational on Tuesday. (Kim McDarison photos.)

Fort Atkinson High School Automotive Instructor Justin Buntrock points to the school’s alignment machine.

Fort Atkinson High School senior Travis Kutz uses the new four-post lift to work on his Ford F-150 truck.

Automotive instructor Justin Buntrock stands in his classroom at Fort Atkinson High School.

Students enrolled in automotive classes can become certified by taking the ASE (automotive service excellence) test. Passing the test is a bragging right, according to the school’s automotive instructor. Certificates are proudly displayed on the classroom wall.

This post has already been read 1736 times!