By Chris Spangler

A 6-ton crane was hoisted into place last week as construction continued on a $1.35 million expansion of the metal fabrication and welding wing at Madison Area Technical College-Fort Atkinson, 827 Banker Road.

Findorff of Madison is the contractor for the project, which calls for adding 4,703 square feet of new space, as well as remodeling 3,598 square feet of the workshop and classroom areas built in 2013.

Jimmy DeGidio, co-program director of MATC’s Metal Fabrication Program, said that this marks the first phase of a two-year project, and one of its many top features is the crane to transport steel stock.

“The 6-ton crane installed in the new fabrication lab will allow us to back a semi fully into the building,” he explained. “We will be able to load material into the racking or to the equipment so we do not have to store it out in the shed and unload it in the parking lot.”

The crane will ensure safety while providing convenience for both students and staff, particularly during winter and on rainy days.

“Safety was one of the biggest reasons we wanted to incorporate the crane system into the new project, and we successfully did that,” DeGidio said.

On Tuesday, Findorff used a large crane to hoist the 6-ton permanent crane up to the steel superstructure above.

The crane will oversee the new fabrication lab, which is being built on the southwest side of the technical college.

“The key to the whole addition is it allows us to add a piece of equipment we currently didn’t have: a CNC laser,” DeGidio said of the metal-cutting equipment. “That technology is required by the local employers, and now we are able to purchase that machine because we have the additional space.”

The water-jet cutter and CNC (computer numerical control) equipment also will be housed in the new addition, which will provide a clean environment for all metal cutting and fabrication undertaken in the new fabrication lab.

At the same time, the current welding area is being expanded into the former fabrication space.

“In the current fab lab, we are adding an additional nine welding booths. The old fab lab will be turned into a welding classroom,” DeGidio said.

More than doubling the number of welding booths will be a huge boost to the metals program, he noted.

“Currently, we are able to offer (instruction to) 12 to 14 students — usually 12 is the best — because we only have eight welding booths,” DeGidio said. “Part of the fabrication program is welding, the joining process, which usually happens somewhere in the end. So now we are able to expand our capacity to 19 welding booths … and we can have our enrollment probably between 18 and 20.”

That is a coup for MATC’s new Bolt-On Program, which enables a student to earn a one-year degree in both metal fabrication and welding in only about 11 months.

“Our current program, Metal Fabrication, is 31 credits, and now they will have an additional five classes for nine credits to get the one-year welding degree too,” DeGidio said.

“The idea is that students who have participated in the metal fabrication degree program already have satisfied the other classes needed for the one-year welding degree,” he added.

By melding the programs together, students are able to save both time and money.

“We are able to offer one course in the fall and one course in the spring for the Bolt-On Program, which leaves them with six credits to take in the summer,” DeGidio said. “They come back for two months in the summer and complete their one-year diploma in welding.”

MATC’s Bolt-On Program is the first such program in the country.

“We developed the idea of the Bolt-On when we created the fabrication program five years ago,” DeGidio said. “We didn’t have the fabrication program here; we had to develop it here.”

Meanwhile, this year’s construction project also includes outdoor drainage improvements, with a rain garden. And if all goes as planned, phase two of the MATC-Fort Atkinson project next year will call for remodeling the metallurgy lab — which currently is hardly larger than a storage area — and creating an active learning computer classroom.

DeGidio noted that while the inside of the current project is what is most needed for instruction, its exterior will provide MATC-Fort Atkinson more visibility to the passing public.

The addition will boast a red-and-cream brick exterior with the fabrication lab logo, four decorative metal panels and clarestory windows near the roofline to bring light into the fabrication lab.

“The brickwork is just beautiful; we have exposure to the sun,” DeGidio said. “This showcase is to the south, so anyone driving by will look to the north and see the building from Highway 12.

“These metal panels will be removeable so students can create projects and put them inside these (lighted) panels,” he added. “There is a nice lounging area along the façade and people can sit out there and have lunch.”

In the wake of the COVID-19 pandemic closures, DeGidio said that he looks at this year as a time to rebuild, not just the physical structure, but the metals program overall.

“The high schools weren’t in session with the hands-on work; for a year-and-a-half to two years, these students didn’t get the labwork. They didn’t get that introduction in woods, metals, mechanics and the stuff they do in the high schools. That’s 90 percent of our recruiting,” DeGidio said.

“So we’re going to see that lull this year until they get back into session in the fall and then we’ll be recruiting heartily from the senior class to populate our program for next year.”

MATC-Fort Atkinson reaches students from throughout Jefferson County and neighboring communities such as Milton and Cambridge.

“People aren’t going to drive to Waukesha if they live over here or anywhere close,” DeGidio said. “We are building one of the best programs in the country with what we do, with the curriculum, with the Bolt-On, and the equipment we have. We have toured other technical colleges in the country and we will be at the top when we’re finished here. And that’s what we’re hoping for.”

DeGidio, who works with fellow fabrication co-program director Al Weishoff in Madison, credited a great team of instructors and staff contributing to this project, because, he emphasized, “it’s a group effort.”

And integral to that group effort is the advisory board, made up of the local employers.

“We have a very active advisory committee, one of the biggest ones in the college. So we take their advice and they help us,” he said.

“They guide us. They’re the ones that guide the program, they guide all the equipment, and the curriculum,” DeGidio added. “And we take their input to give the students training that the local employers need.”

The current project is expected to be completed the second week of September.

Three graphics above: artist’s drawings show the outside of the completed $1.35 million expansion of the metal fabrication and welding wing at Madison Area Technical College-Fort Atkinson.

Graphics supplied.

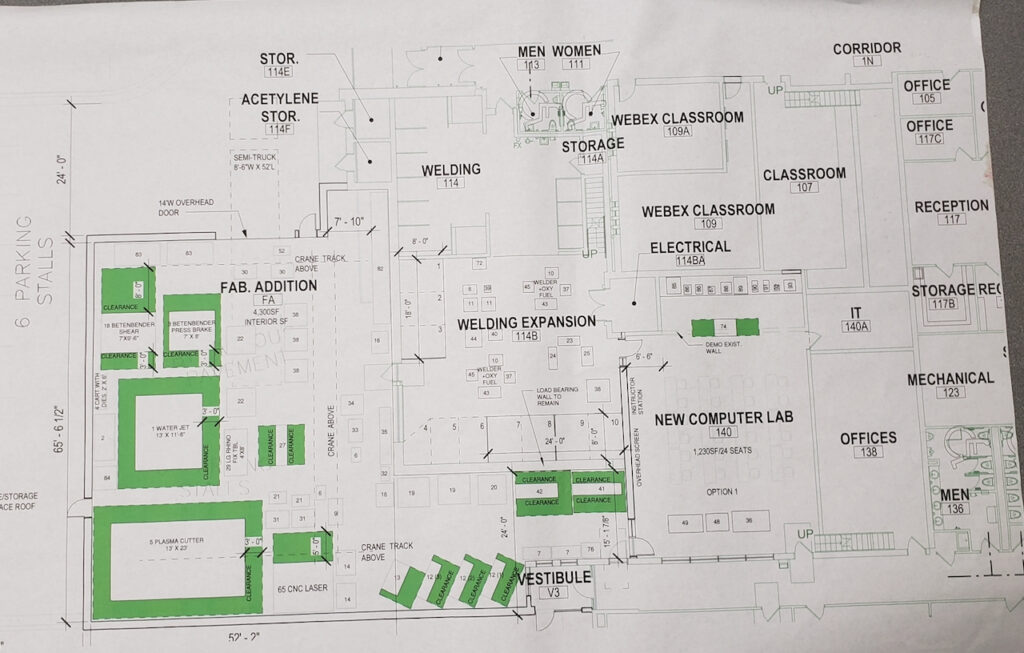

Floor plans show placement of the new addition and other improvements under construction at Madison Area Technical College-Fort Atkinson. Graphic supplied.

A crane is used to place a permanent overhead crane into the new fabrication lab at Madison Area Technical College-Fort Atkinson. The work was undertaken last Tuesday. Photo courtesy of Jimmy DeGidio.

The new permanent crane pictured after placement.

Jimmy DeGidio, fabrication program co-director and welding instructor at Madison Area Technical College-Fort Atkinson, shows the space into which the welding area is being expanded as part of a $1.3 million construction project.

The current metallurgy area is located in a storeroom-type space. Phase two of the MATC-Fort Atkinson project, planned for next year, calls for remodeling the metallurgy lab and creating an active learning computer classroom.

A construction crew works on a $1.35 million expansion at MATC-Fort Atkinson, which includes building a new fabrication lab.

Construction of a new fabrication lab is well under way at MATC-Fort Atkinson. The project is expected to be completed by mid-September.

Jimmy DeGidio, fabrication lab co-program director and welding instructor at MATC-Fort Atkinson, left, chats with Findorff assistant project manager Jon Winch, center, and project superintendent Jeff Alexander, right, in the new fabrication lab area being built.

Construction is well underway on a new addition and remodeling project for the welding and fabrication lab at MATC-Fort Atkinson. Findorff of Madison is the contractor.

Photos by Chris Spangler unless otherwise indicated.

This post has already been read 2286 times!